Why Earth's Best Optical Fiber Can Only Be Made in Space

The incredible benefits of ZBLAN optical fiber and why it needs microgravity, and which companies are building in-space manufacturing and offering microgravity-as-a-service.

Welcome to a 🔒 subscriber-only Sunday deep-dive edition 🔒 of my weekly newsletter. Each week, I help readers learn about chip design, stay up-to-date on complex topics, and navigate a career in the chip industry.

As a paid subscriber, you will get additional in-depth content, and also get to suggest topics for this newsletter using this form. We also have student discounts and lower pricing for purchasing power parity (see discounts). See here for all the benefits of upgrading your subscription tier!

If you’re interested in photonics, here is content you’re missing out on without a paid subscription.

This post is too long for email. Please read it on Substack by clicking on the title.

Every revolutionary idea seems to evoke three stages of reaction.

It’s completely impossible

It’s possible but not worth doing

I said it was a good idea all along

— Arthur C. Clarke

Fifty or more years ago, we were in complete denial that manufacturing in space was a possibility, firmly rooted at the first stage of Arthur C. Clarke’s reaction stages. Then, 3D printing demonstrations run aboard SkyLab in 1973 showed that it was possible, but the cost of space launches was astronomical. Enter stage two.

Today, if you look at the sheer number of startups working to commercialize manufacturing in space for everything from materials, optics, and semiconductors to pharmaceuticals, prosthetics, and drug discovery, you could argue that the innovation train has reached its final destination: stage three.

One of the strongest reasons to manufacture in space: microgravity.

In this post, we will look at why in-space manufacturing and microgravity enables us to make materials that are simply not possible on Earth. More specifically, we will recount the discovery and manufacturing of a very unique glass that still holds potential to upend the fiber optic industry, and also explain why that has not happened yet.

Here’s an overview for free subscribers:

Microgravity: What makes it unique, and what physical phenomena are absent.

Origins of in-space manufacturing: Early experiments on board Skylab showed that 3D printing was possible in-situ.

Discovery of heavy metal fluoride glass: The accidental discovery of a remarkable material for optical fibers: ZBLAN.

Remarkable optical properties: The low-loss, wide bandwidth and zero dispersion properties of ZBLAN meant that losses could be up to 100x lower than common silica fiber.

Trouble making it happen: Whenever ZBLAN optical fibers were made, it just did not have the low-loss properties everybody wanted. Gravity was the problem.

Getting rid of gravity: There are many ways to get rid of gravity, but early attempts at making ZBLAN were borderline insane.

Why ZBLAN did not eat world: There are reasons we still use silica fiber. But ZBLAN is still amazing for mid-IR applications.

🔒 For paid subscribers:

Comprehensive list of 13 companies working on manufacturing in microgravity

Including funding, engineering focus, notable achievements and links.

The Uniqueness of Microgravity

The near absence of gravity found in Low-Earth Orbit (LEO) is a degree of freedom for material manufacturing that is afforded nowhere on Earth. Several physical phenomena are greatly attenuated in such an environment.

No buoyancy and sedimentation: In gravity, differences in material density cause heavier substances to sink and lighter substances to float. Microgravity provides increased uniformity.

No convection: When liquids and gases heat up, they get lighter and move to the top. In microgravity, this phenomenon does not occur. Mixing only occurs by diffusion which can be performed accurately in very small quantities.

No (or extremely low) pressure: The air above the earth exerts pressure close to the Earth’s surface (called 1 atmosphere), which is significantly reduced in space.

No containers: Liquids and gases need containers on Earth which they have to touch. No containers are needed in microgravity, which means there are no container size constraints or contamination issues (for example: the high purity quartz container needed to melt silicon is a story all of its own.)

With the absence of multiple physical phenomena in a microgravity environment, manufacturing materials in space offers a lot of advantages.

Origins of in-space manufacturing

The idea of making materials in space is not new. In-space manufacturing has been a dream for the last 50 years starting with experiments performed during NASA’s 1973 Skylab mission to understand the effects of microgravity on manufacturing, in which astronauts experimented with crystal growth in zero-gravity environments. For the longest time after that, in-space manufacturing was mostly forgotten because it was simply too expensive.

Excluding the spur of activity in the 1990s, which is a story we will explore in detail in the next section, in-space manufacturing got a new lease on life when Made in Space demonstrated 3D printing aboard the International Space Station (ISS). This milestone is significant because it meant that spare parts could be printed on-demand in space without relying on supplies from Earth. If any specific tooling was necessary aboard the space station or specific equipment was needed for scientific experiments, the astronauts could simply print one if a design file was sent up to them. They could also repurpose 3D printed objects to fashion them into other useful tools by recycling plastic.

The tools 3D printed in microgravity showed no noticeable difference compared to the ones made on Earth. However, the extraordinary benefits of harnessing the power of microgravity lies in the manufacturing of other materials — such as optical fiber.

Discovery of heavy metal fluoride glasses

There was a sudden flurry of activity in space manufacturing during the 1990s primarily due to a revolutionary glass material that could completely disrupt the optical fiber industry. It is a story worth telling.

In 1974, two brothers Michel and Marcel Poulain who were researchers at the University of Rennes working on solid state chemistry, were investigating new fluoride complexes based on zirconium fluoride. They accidentally managed to create an amorphous crystal (an oxymoron by itself) that broke all known models of what glass structure should look like. The material was ZrF4-BaF2-LaF3-AlF3-NaF, or ZBLAN for short, and belonged to the family of heavy metal fluoride glasses. In 1977, they started a company called La Verre Fluoré to commercialize this unique material for fiber applications due to its startling properties.

The Incredible Properties of ZBLAN

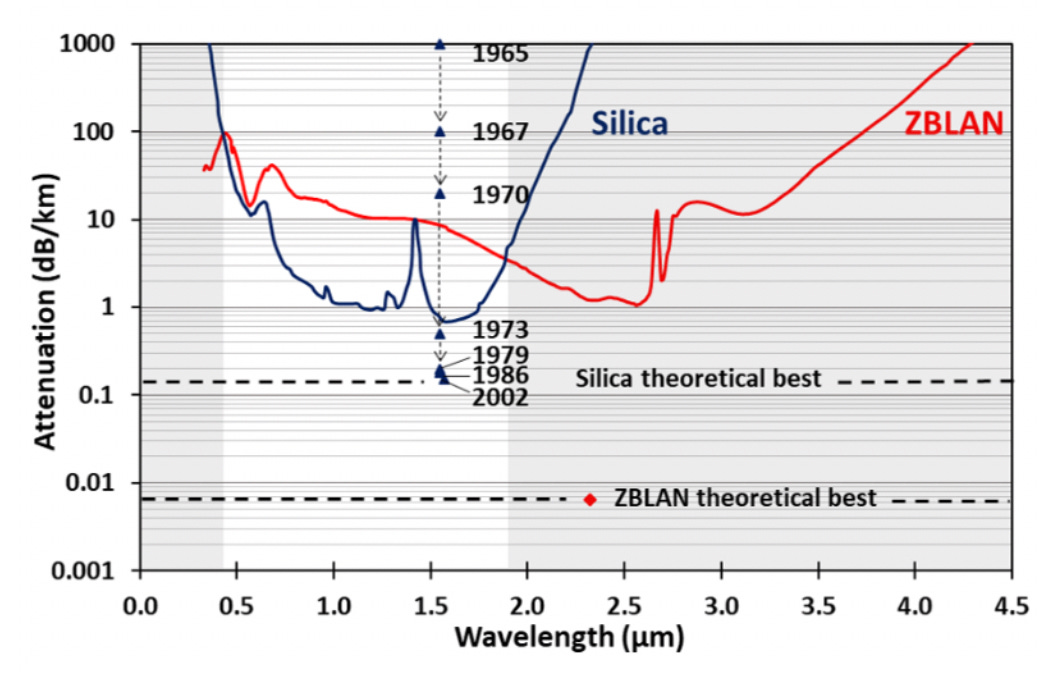

The interesting property of ZBLAN is its ultra low signal losses when used as an optical fiber core material — a theoretical best of 10-100x better than the commonly used silica glass fibers. For example, a 2,000 km length of ZBLAN optical fiber would have the same loss as a 10 km long silica fiber. Such low loss would greatly reduce the need for optical amplifiers in transcontinental optic fiber links which currently span the entire globe covering 1.2 million kilometers across 500 cables. But as the plot below shows, ZBLAN has much higher losses than it is inherently capable of. We will understand why shortly.

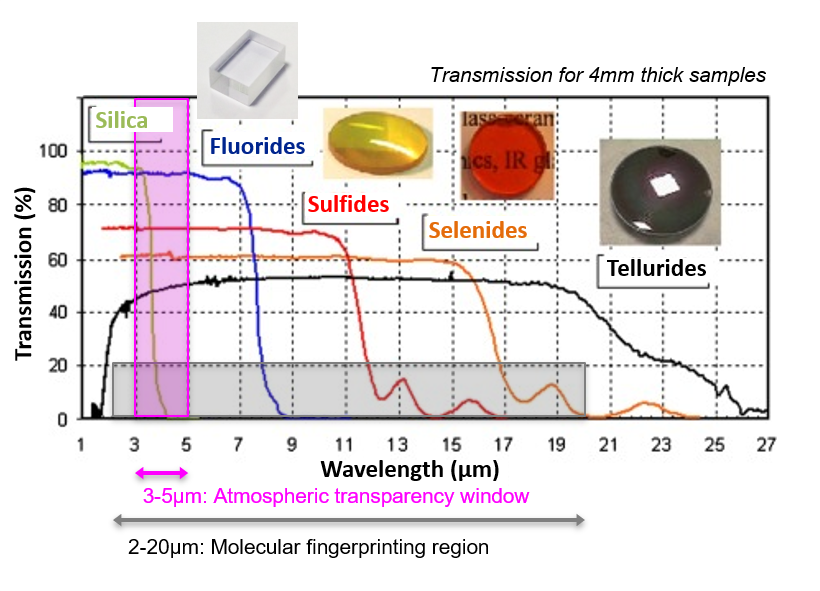

Another highly desirable property of ZBLAN being a fluoride glass is its very wide optical transmission window for wavelengths ranging from 0.4 microns to 4 microns (some fluoride glasses even work up to 7 micron wavelengths) with low transmission losses. This makes it useful for near-infrared or mid-infrared applications like spectroscopy.

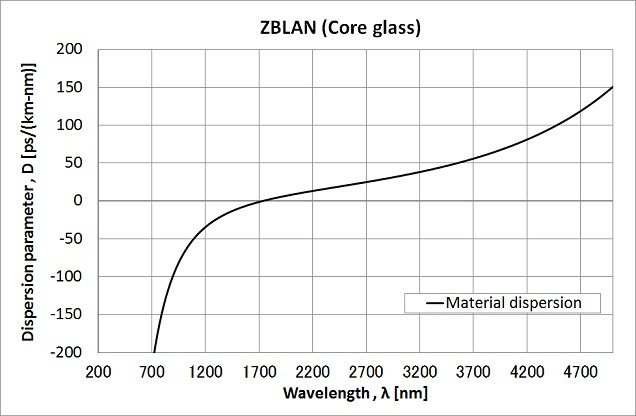

To keep stacking advantages, ZBLAN also has a narrow wavelength range where the dispersion — an unwanted phenomenon of light spreading that distorts signals traveling through the optical fiber — goes to almost zero. By great stroke of luck, this happens to coincide with a wavelength of 1.7-1.9 microns where commercial high power pulsed sources are widely available.

Trouble in optical paradise

The benefits of ZBLAN are undeniable, but sadly it is hard to manufacture ZBLAN and harness its amazing properties. Any kind of optic fiber manufacturing usually involves a large diameter glass mixture called preform on top of a large tower sometimes several stories tall, called a draw tower. A bead of glass is dropped from the mixture which pulls a glass fiber behind it, much like a confectioner pulls taffy. There is a spool that is rotating at the bottom of the draw tower continuously winding the fiber and pulling from the preform.

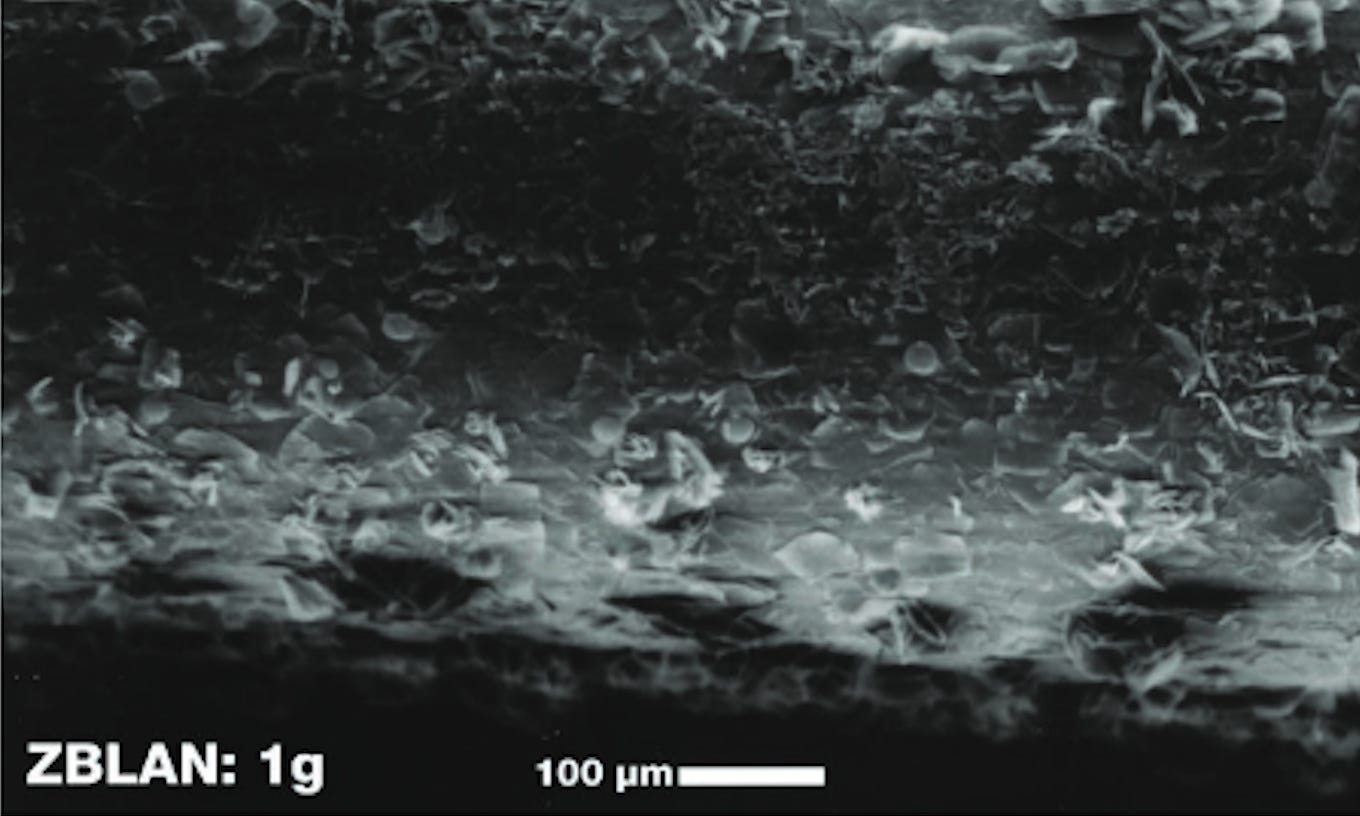

Manufacturing ZBLAN optical fibers this way forms defects in the fiber due to formation of tiny crystals due to convection effects in the presence of gravity. As a result, a lot of magic of ZBLAN is greatly diminished due to light scattering from the formation of microcrystals. This is why ZBLAN has high loss in the attenuation plot shown earlier.

Getting rid of pesky gravity

But the benefits of ZBLAN were too great for NASA to ignore, and so if gravity was affecting the production of ZBLAN, it was time to get rid of it — at least here on Earth.

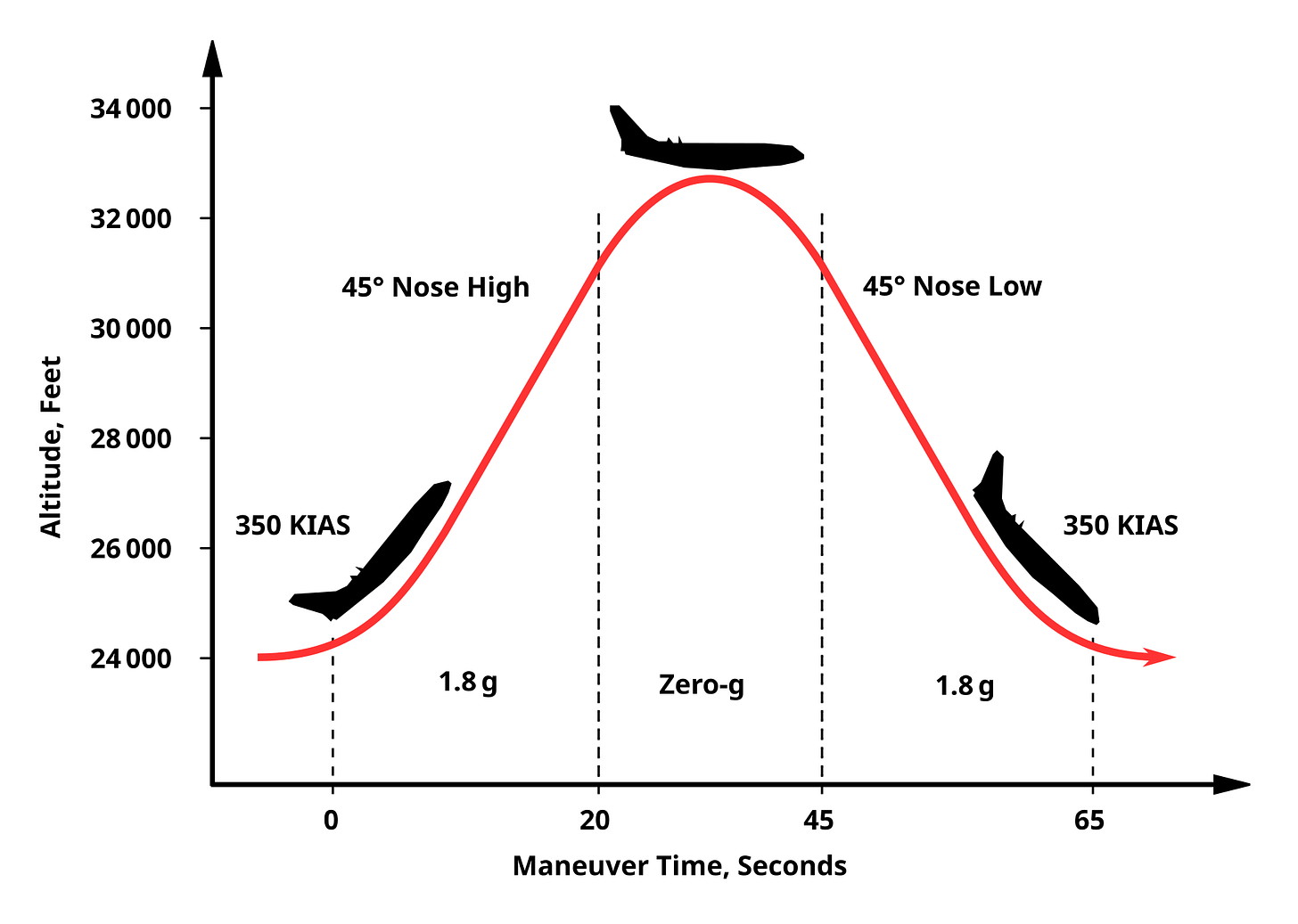

They loaded up equipment to manufacture ZBLAN onto a KC-135 aircraft popularly known at the '“Vomit Comet” commonly used for astronaut training. The way this aircraft works is that it flies in a vertical parabolic arc much like a roller coaster during which a 25 second period of microgravity is created at the inflection of the parabola. In April of 1994, the aircraft was launched from the White Sands Missile Center in New Mexico and ZBLAN was manufactured during the period of microgravity encountered on the flight.

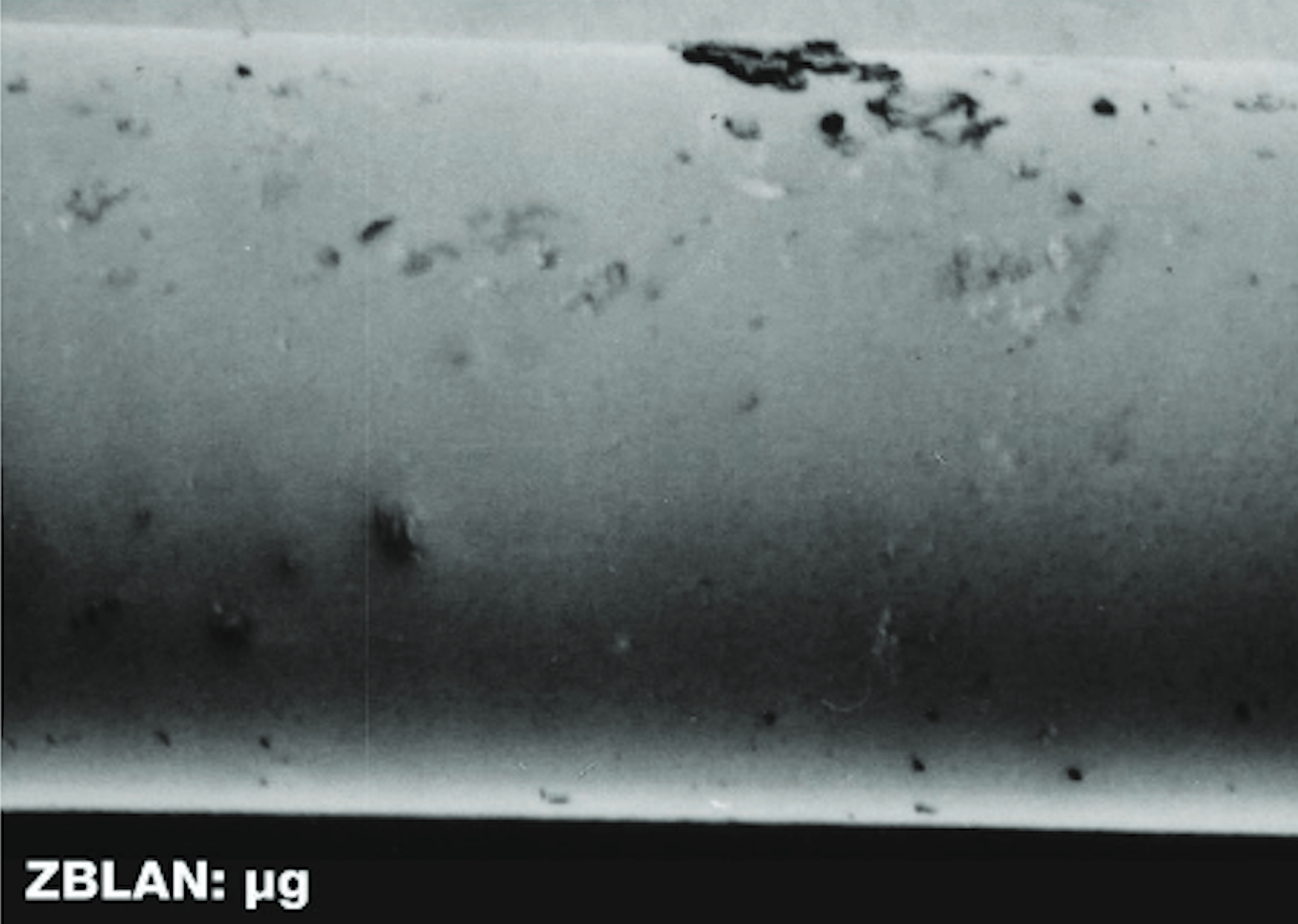

Post flight, NASA was able to prove that a microgravity environment does cause a reduction in the formation of microcrystals in ZBLAN as you can see in the picture below. 25 seconds was an insufficient amount of time to make any significant amount of fiber, but it showed proof of concept. NASA figured they needed more like two minutes at the very least to study all the details of ZBLAN production in microgravity. You can read the whole report here.

Bye-bye gravity, hello space

To make any significant amount of fiber, it was obviously better to move production to actual space, and not simulated environments. Between 2017 and 2019, several companies such as Fiber Optics Manufacturing in Space (FOMS) (San Diego, CA), Made in Space (Mountain View, CA) and Physical Optics Corporation (Torrance, CA, who were later acquired by Mercury Systems in 2020) all demonstrated ZBLAN manufacturing aboard the ISS. These companies have been continuously improving their in-space fiber production systems using zero-gravity testing on Earth using services provided by companies like Zero-G1.

Notable progress however has been made by Flawless Photonics (Reno, NV). In 2024, they demonstrated about 7 miles of ZBLAN production in one month aboard the ISS. Their production rate exceeds about 1 kilometer per day. These space drawn fibers were then sent to earth and the comparison in quality is seen below. You can tell that the fiber manufactured in microgravity has far fewer defects.

Why ZBLAN did not eat world

If you’re wondering why all telecommunications infrastructure has not yet switched over to ZBLAN, there are a few major reasons:

Loss performance: For a wide range of useful wavelengths, silica fiber still provides the lowest loss. ZBLAN is theoretically better, but practical implementations of ZBLAN fibers have poorer performance compared to silica.

Cost: Silica-based optical fiber is priced at about $0.1-0.5 per meter, while Earth-manufactured ZBLAN is already 1,000-10,000X that price at $150-1,000 per meter. Microgravity-made ZBLAN could easily cost an order of magnitude higher.

Mechanical properties: ZBLAN fibers are much more brittle and have a larger bending radius compared to silica fibers, which makes them much harder to handle.

Due to these limitations, ZBLAN is limited to specialized, high-value, and often niche applications often involving mid-infrared wavelengths. If you’re building anything in the 2–4.5 µm optical band, ZBLAN is effectively the only real option available today at semi-commercial scale.

Comprehensive list of companies working on manufacturing in microgravity

Clearly, the benefits of microgravity are undeniable for optics applications but there are many other potential uses-cases. For starters, Texas A&M University (my alma mater) is now running a ‘Chips in Space’ research program to pioneer space-based semiconductor manufacturing. With declining launch costs due to reusable rocket platforms by SpaceX and others, there is a burgeoning industry to harness the benefits of microgravity or provide microgravity-as-a-service.

If you’re interested in how space manufacturing is moving from experiment to industry, the section below for paid subscribers includes a roundup of thirteen companies doing the actual work. It’s a snapshot of leading companies that includes funding details, technical focus, and notable projects for anyone curious about where the next phase of space-based manufacturing might unfold.